After 10-12 years of operation, photovoltaic inverters need a “refresh.” By now it is well known. What is less clear, however, is what should be done to restore them to their original performance standard. Many people think it is enough to replace the electrolytic capacitors and cooling fans to have performed what insiders like to call “tenth-year maintenance.”

Experience has shown that this is not the case. A photovoltaic inverter is a complex object composed of various elements, both “central” and “peripheral”; to properly manage this equipment, one must have a thorough understanding of its operating logic, as well as be able to interpret the context within which it is placed.

Specialized extraordinary maintenance done properly cannot go without a thorough overhaul of the entire converter. All of its component parts should be checked, even those that may seem minor at first glance. This is the case, for example, with “minor” components that, however, perform an essential function for the proper functioning of the converter.

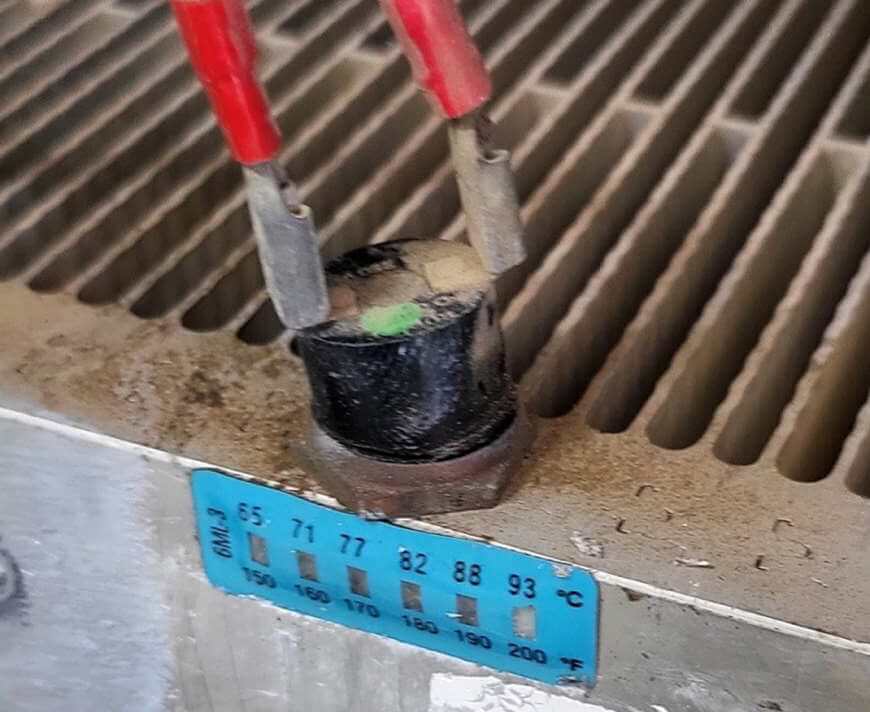

Take, for example, operating temperature detection systems. All inverters, in fact, are equipped with internal temperature detection and control systems through the use of thermal probes typically installed at critical points (from a heat production point of view) of the converter.

These sensors also degrade after a prolonged period of operation, perhaps under environmentally unsuitable conditions, due to external agents such as dust accumulation, humidity, and temperature changes. Failure of these devices can cause serious damage to the machine, which, in the absence of accurate information about the internal temperature, may, for example, fail to activate self-protection mechanisms (e.g., derating) that can safeguard its functional integrity.

Amperometric Transducers (TAs) are devices that can convert the value of the measured current into a signal, either analog or digital, which is normally sent to the Control Unit (Motherboard) that is responsible for reading the information, interpreting it and deciding what action to take.

In the case of photovoltaic inverters, these devices play a very important role because they provide valuable information to the “brain” of the machine about the actual operation of the machine. In particular, they provide the Gate Units with the essential parameters for the proper driving of the IGBTs and send the necessary feedback to the Control Unit to perform any necessary correction actions.

If these devices fail or stop functioning properly, they risk sending the wrong information to the control/command bodies of the inverter, jeopardizing not only the functionality of the inverter, but even its physical integrity.

After 10-12 years of operation, often under unsuitable environmental conditions, TAs usually show the unmistakable signs of aggression from external agents (e.g., dust, moisture, etc.). In the device pictured in the photo, for example, 2 of the 4 PINs of the connector were literally “eaten” by obvious oxidation phenomena. A CT in this condition can cause, at best, unwanted downtime and, at worst, extensive damage to the power part of the inverter.

Photovoltaic inverters also are equipped with a series of electronic boards that are, in fact, their command, control and communication section. These electronic boards (Gate Units, Control Units, Power Supply, etc.) are physically connected to each other by means of various types of connector systems that are intended to enable the transfer of information through a predefined communication protocol.

Any interference on the free flow of this information could cause unexpected failure and/or malfunction of the converter. In the case of photovoltaic inverters, which are often installed in rooms characterized by harsh environmental conditions, it is essential to ensure that these devices are not compromised by external agents (e.g., dust, copper oxide, etc.) that can cause an interruption in the “logic chain” of machine operation.

The Gate Unit – Control Unit connection connector pictured in the photo, for example, is rendered unserviceable by obvious accumulations of dust and debris deposited on the very contact part of it (PIN). In these cases, the minor damage is downtime; in the worst cases, on the other hand, the circulation of incomplete and/or inconsistent data can trigger unsuitable behavior that can compromise the functional integrity of the inverter.

In short, to be sure that the inverter will continue to produce clean energy efficiently and safely into the second part of its technical useful life, it is necessary to undergo a regeneration process that includes an overhaul of all, bar none, of the “sensitive” systems of the converter.

If it is true that the essential is invisible to the eyes, one must know where to look for it.